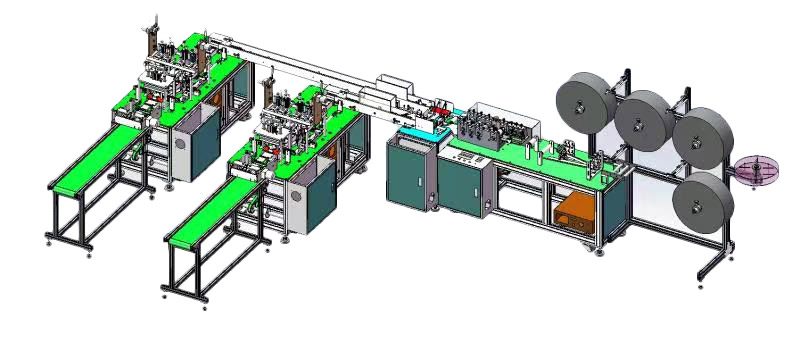

1.The connecting part of the whole machine is 1:6500(L)×3500(W)×1950(H) mm.

Voltage :220 VAC±5%50 HZ rated power :≤10 KW (including welder)

2.Production :100 PCS/min.

High

3.Stability, low failure rate, beautiful and strong not rust.

4.PLC programming control, servo drive, high degree of automation.

5.Photoelectric (optical fiber) to detect raw materials to avoid errors and reduce waste.

This machine is fully automatic production folding mask body machine, the main process:

5.1 Includes automatic delivery of raw materials.

5.2 Automatic delivery.

5.3 Cut off the bridge of the nose.

5.4 Mask edge welded.

5.5 Fold.

5.6 Ultrasonic fusion.

5.7 Full process automation such as molding cut-off.

I. GENERAL PROVISIONS

1. this specification is applicable to the one-time use of one-towed two-mouth cover machine sold by China domestic Research Institute.

2. machine is a fully automatic line with a maximum capacity of 24 hours at full load can theoretically reach 12~140000 per day (the delay in refueling may be slightly less than the theoretical value).

3. external ear mask machine can only produce disposable plane mask, whether the mask produced by this machine has nothing to do with the machine, as long as the mask is sterilized, the mask produced by this machine can be used as a surgical medical mask.

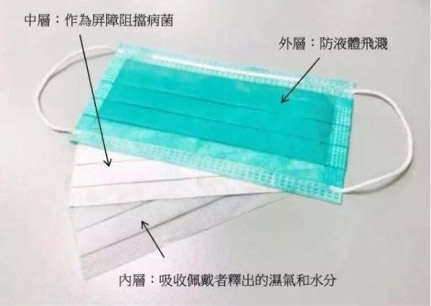

4. common medical masks: mainly composed of three layers of non-woven cloth. The inner layer is an ordinary non-woven fabric; the outer layer is a waterproof non-woven fabric, mainly used to insulate the liquid ejected by the patient; the middle filter layer is a electret treated polypropylene melt-blown non-woven fabric; After the final production, ethylene oxide disinfection and analysis, packaging, packing away.

II. Technical parameters

Machine connection:

1. whole machine connection part one tow two machine table size :6500(L)×3500(W)×1950(H) mm.

Voltage :220 VAC±5%50 HZ rated power :≤10 KW (including welder)

2. production :100 PCS/min.

High 3. stability, low failure rate, beautiful and strong not rust.

4.PLC programming control, servo drive, high degree of automation.

5. photoelectric (optical fiber) to detect raw materials to avoid errors and reduce waste.

This machine is fully automatic production folding mask body machine, the main process:

5.1 Includes automatic delivery of raw materials.

5.2 Automatic delivery.

5.3 Cut off the bridge of the nose.

5.4 Mask edge welded.

5.5 Fold.

5.6 Ultrasonic fusion.

5.7 Full process automation such as molding cut-off.

Host part:

1. mechanical specifications

Production pass rate :96 per cent

2. mechanical characteristics

2.1 Automatic tension control of raw materials to ensure tension balance of raw materials.

2.2 Computer program control, high output, good stability, low failure rate.

2.3 Optoelectronic detection of raw materials to avoid errors and reduce waste.

2.4 One to four layers of mask body can be produced.

2.5 The machine has total count and batch count function, the number of batch count can be set arbitrarily.

2.6 Mould replacement can produce masks of different sizes and styles.

2.7 The whole machine adopts aluminum alloy structure, beautiful and strong without rust.

2.8 Mechanically adjustable part: the folding part can be adjusted;

3. mechanical 1-4 cloth mask (with activated carbon material in the middle); weld strength can be adjusted.

III. Product Picture

IV. USE REQUIREMENTS

The number of automatic production line needs 3 people, if cancel the conveyor belt need to increase 2 people.

V. Pictures of finished products