Nitrogen diaphragm compressors can be used for nitrogen recovery compressors, nitrogen filling bottles, nitrogen booster compressors, and high-purity nitrogen filling (99.999% or more). Common working conditions are used for nitrogen recovery after liquid nitrogen vaporization, so that the nitrogen pressure in the tank does not exceed 8kg, so as to avoid the waste of nitrogen pressure increase and emptying. A small nitrogen diaphragm compressor costs about 50,000 to 60,000 yuan, and can fill 3 to 4 bottles of 40L steel cylinders of nitrogen per hour, with a pressure of 150kg.

Nitrogen diaphragm compressors can be used for nitrogen recovery compressors, nitrogen filling bottles, nitrogen booster compressors, and high-purity nitrogen filling (99.999% or more). Common working conditions are used for nitrogen recovery after liquid nitrogen vaporization, so that the nitrogen pressure in the tank does not exceed 8kg, so as to avoid the waste of nitrogen pressure increase and emptying. A small nitrogen diaphragm compressor costs about 50,000 to 60,000 yuan, and can fill 3 to 4 bottles of 40L steel cylinders of nitrogen per hour, with a pressure of 150kg.

Nitrogen diaphragm compressors can be used interchangeably with argon compressors, etc., and the operating parameters need to be informed for technical customization.

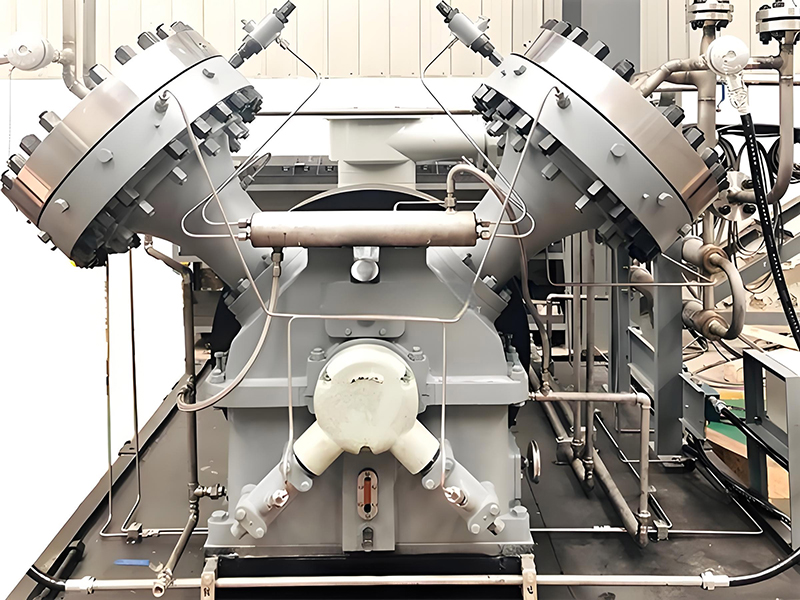

Diaphragm compressors are divided into ZXGZ, ZXGV, ZXGL and ZXGD types according to different structural forms, among which the stability is ZXGZ type < ZXGL type < ZXGV type < ZXGD type. The structure is divided into these forms mainly based on the calculation of piston thrust and cylinder size. The piston thrust of general GZ diaphragm compressor ranges from 1 ton to more than 4 tons, the piston thrust of ZXGV diaphragm compressor is 1 ton and 3 tons, the piston thrust of ZXGL diaphragm compressor is 2 tons and 4 tons, and the piston thrust of ZXGD diaphragm compressor is 4 tons, 6 tons, 8 tons, 10 tons, 16 tons. Our company's diaphragm compressor products basically cover the whole series, which can meet your customized compressor needs. The flow rate can range from 1NM3/h to 1500NM3/h (depending on the intake and exhaust pressure). According to different parameters, the motor power can range from 2.2kw to 200kw. Diaphragm compressors are now widely used in various gases, including tetrafluoroethylene, gas, ammonia, propylene, nitrogen, oxygen, helium, hydrogen, hydrogen chloride, argon, hydrogen chloride, hydrogen sulfide, hydrogen bromide, ethylene, acetylene, etc.

When your company needs to inquire about the compressor parameters, please pay attention to providing at least the following parameters so that our company can provide you with accurate models or solutions in a timely manner.

1. Suction pressure: also known as inlet pressure, that is, the pressure value of the buyer's gas source (the pressure loss in the pipeline between the gas source and the diaphragm compressor suction port is not considered for the time being);

2. Exhaust pressure: also known as outlet pressure, that is, the working pressure required by the buyer's system;

3. Suction temperature: that is, the temperature of the buyer's gas source (the temperature loss in the pipeline between the gas source and the diaphragm compressor suction port is not considered for the time being);

4. Exhaust temperature: also known as outlet temperature. That is, the temperature measured at the exhaust port of the diaphragm compressor after the gas is compressed. This temperature should be lower than the temperature allowed by the compression medium;

5. Gas supply temperature: also known as the temperature of the exhaust gas after cooling. The high-temperature gas discharged from the exhaust port of the diaphragm compressor is cooled by the compressor's own cooling system and is used by the buyer;

6. Compressed medium: also known as compressed gas. If it is a mixed gas, the components of the mixed gas, the proportion of each component in the mixed gas, and the characteristics of the compressed medium should be provided;

7. Volume flow rate: also known as exhaust volume or gas supply volume, that is, the gas volume required per unit time at the above-mentioned suction pressure and exhaust pressure, generally under standard conditions, that is: standard gas volume per hour (Nm3/H);

8. Electrical explosion-proof level and specific requirements and special requirements for diaphragm compressor automatic control;

9. Foreign customers should specify the voltage and frequency of the power supply when placing orders.